All Services

- Tank Valve Remote Control System Services

- Alarm Monitoring & Tank Gauging Monitoring System Services

- Main Switchboard & Loadsharing Maintanence And Repair Service

- Engine & Aux Gen. Governor System Repair

- Alternator System Repair Services

- Automation and Electric Electronic Spare Part Support

- Automation Service

- Electronic Card Repair

- PLC Software and Hardware Support

- Deck Crane Automation Repair Service

Do you need support?

Introduction: Electronic cards serve as the backbone of numerous devices and systems, facilitating the operation of everything from industrial machinery and medical equipment to consumer electronics and telecommunications networks. However, like any electronic component, these cards are susceptible to damage, malfunction, and wear over time. When issues arise, electronic card repair services play a crucial role in restoring functionality, minimizing downtime, and prolonging the lifespan of electronic devices.

Location :

Compliance :

Dimension :

Roof slope :

Crane System :

Understanding Electronic Card Repair: Electronic cards, also known as circuit boards or PCBs (Printed Circuit Boards), consist of intricate circuits, components, and connectors that enable the transmission and processing of electronic signals. When these cards malfunction due to factors such as component failure, environmental factors, or manufacturing defects, electronic card repair services come into play. These services involve diagnosing the root cause of the problem, repairing or replacing faulty components, and testing the card to ensure proper functionality.

Common Issues Addressed by Electronic Card Repair Services: Electronic card repair services are capable of addressing a wide range of issues, including:

- Component Failure: Failed components such as capacitors, resistors, integrated circuits, or connectors can impair the functionality of the electronic card.

- Physical Damage: Physical damage such as cracked traces, broken connectors, or delamination can occur due to mishandling, accidents, or environmental factors.

- Solder Joint Defects: Poor solder joints, solder cracks, or cold solder joints can lead to intermittent connections or open circuits, causing malfunction.

- Environmental Factors: Exposure to moisture, heat, dust, or corrosive substances can degrade the performance and reliability of electronic cards over time.

- Manufacturing Defects: Defects introduced during the manufacturing process, such as soldering defects or design flaws, can manifest as reliability issues in electronic cards.

Key Considerations in Electronic Card Repair: Effective electronic card repair services adhere to the following key considerations:

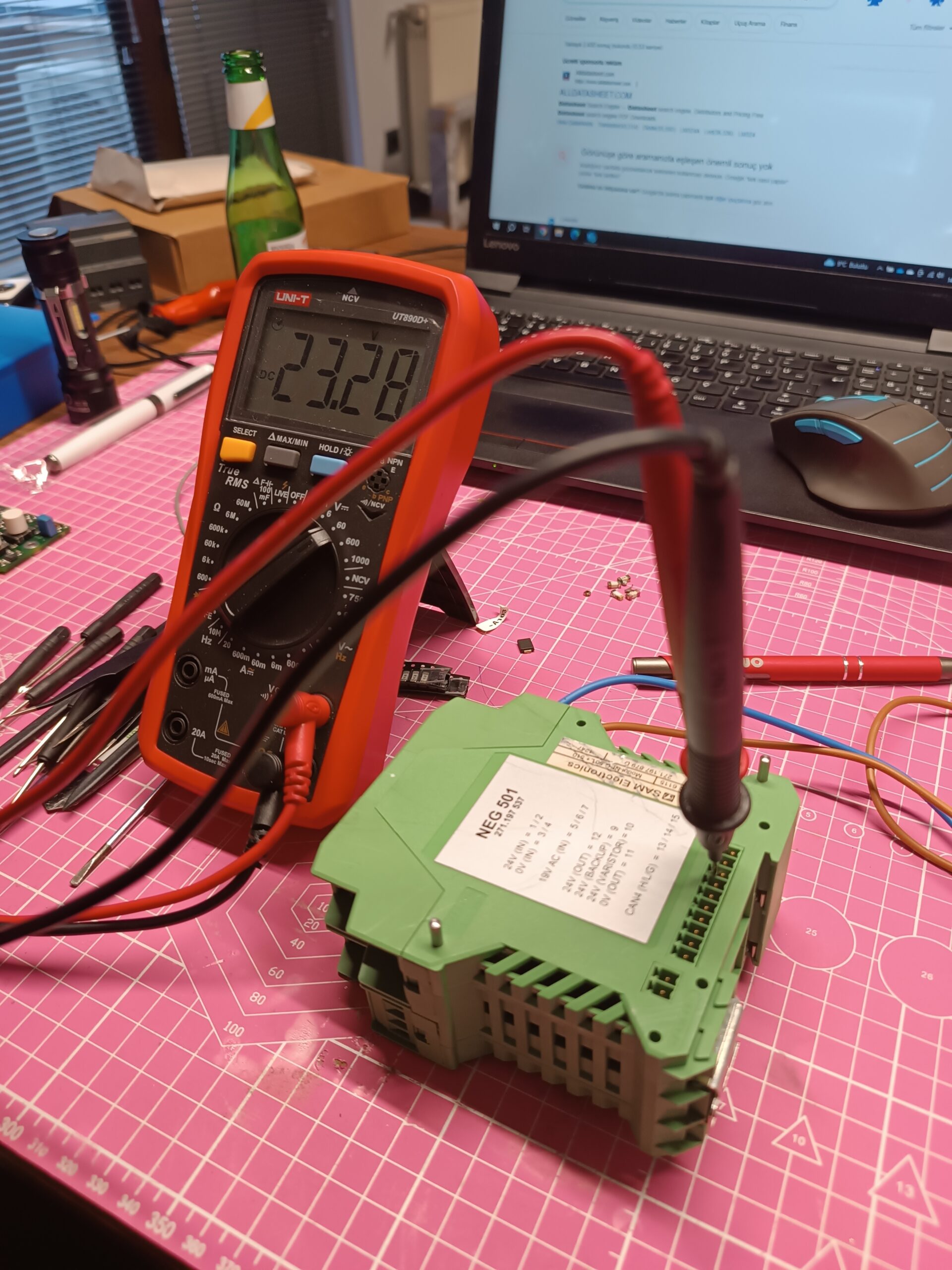

Diagnosis and Analysis: Thorough diagnosis and analysis of the electronic card are essential to identify the root cause of the problem accurately. This may involve visual inspection, functional testing, and the use of diagnostic equipment such as multimeters, oscilloscopes, and logic analyzers.

Component-Level Repair: Skilled technicians perform component-level repair, which involves identifying and replacing faulty components such as capacitors, resistors, integrated circuits, and connectors. Surface-mount technology (SMT) and through-hole components may require specialized tools and techniques for removal and replacement.

Soldering and Rework: Proper soldering and rework techniques are critical to ensuring reliable connections and avoiding damage to the electronic card. Techniques such as reflow soldering, hand soldering, and hot-air rework may be employed depending on the complexity of the repair.

Testing and Validation: After repairs are completed, the electronic card undergoes rigorous testing and validation to ensure proper functionality and performance. This may involve functional testing, in-circuit testing (ICT), boundary scan testing, and environmental testing to simulate real-world conditions.

Quality Assurance: Quality assurance measures, such as adherence to industry standards (e.g., IPC-A-610), use of high-quality components, and proper handling procedures, are essential to maintaining the integrity and reliability of the repaired electronic card.

Conclusion: In conclusion, electronic card repair services play a vital role in maintaining the functionality, reliability, and longevity of electronic devices and systems. By addressing issues such as component failure, physical damage, and manufacturing defects, these services help organizations minimize downtime, reduce costs, and extend the lifespan of their investments. Whether it’s through skilled diagnosis, component-level repair, or rigorous testing and validation, electronic card repair services provide the expertise and resources needed to keep electronic devices running smoothly in today’s technology-driven world.

What we can do for you :

Customize according to needs

We can customize our service according to the amount of goods you want to store.

Reduce your costs

You will not have to invest to build and operate a private warehouse

Shorten your cycle time

Shorten your cycle time is the benefit warehousing service bring for businesses.

Increase operation efficiency

Warehousing service help reduce cost & save you time