All Services

- Tank Valve Remote Control System Services

- Alarm Monitoring & Tank Gauging Monitoring System Services

- Main Switchboard & Loadsharing Maintanence And Repair Service

- Engine & Aux Gen. Governor System Repair

- Alternator System Repair Services

- Automation and Electric Electronic Spare Part Support

- Automation Service

- Electronic Card Repair

- PLC Software and Hardware Support

- Deck Crane Automation Repair Service

Do you need support?

Introduction: Programmable Logic Controllers (PLCs) are the backbone of automation systems, controlling and monitoring industrial processes across various sectors. To ensure the seamless operation of PLC-based systems, comprehensive software and hardware support services are essential.

Understanding PLC Software and Hardware Support: PLC software and hardware support services encompass a range of offerings aimed at maintaining, troubleshooting, and optimizing PLC-based systems. This includes software programming, diagnostics, firmware updates, hardware repair, and component replacement to address issues and ensure the continued functionality of PLCs. Whether it’s routine maintenance, emergency repairs, or system upgrades, these services are critical for minimizing downtime and maximizing the efficiency of industrial automation processes.

Key Components of PLC Software and Hardware Support:

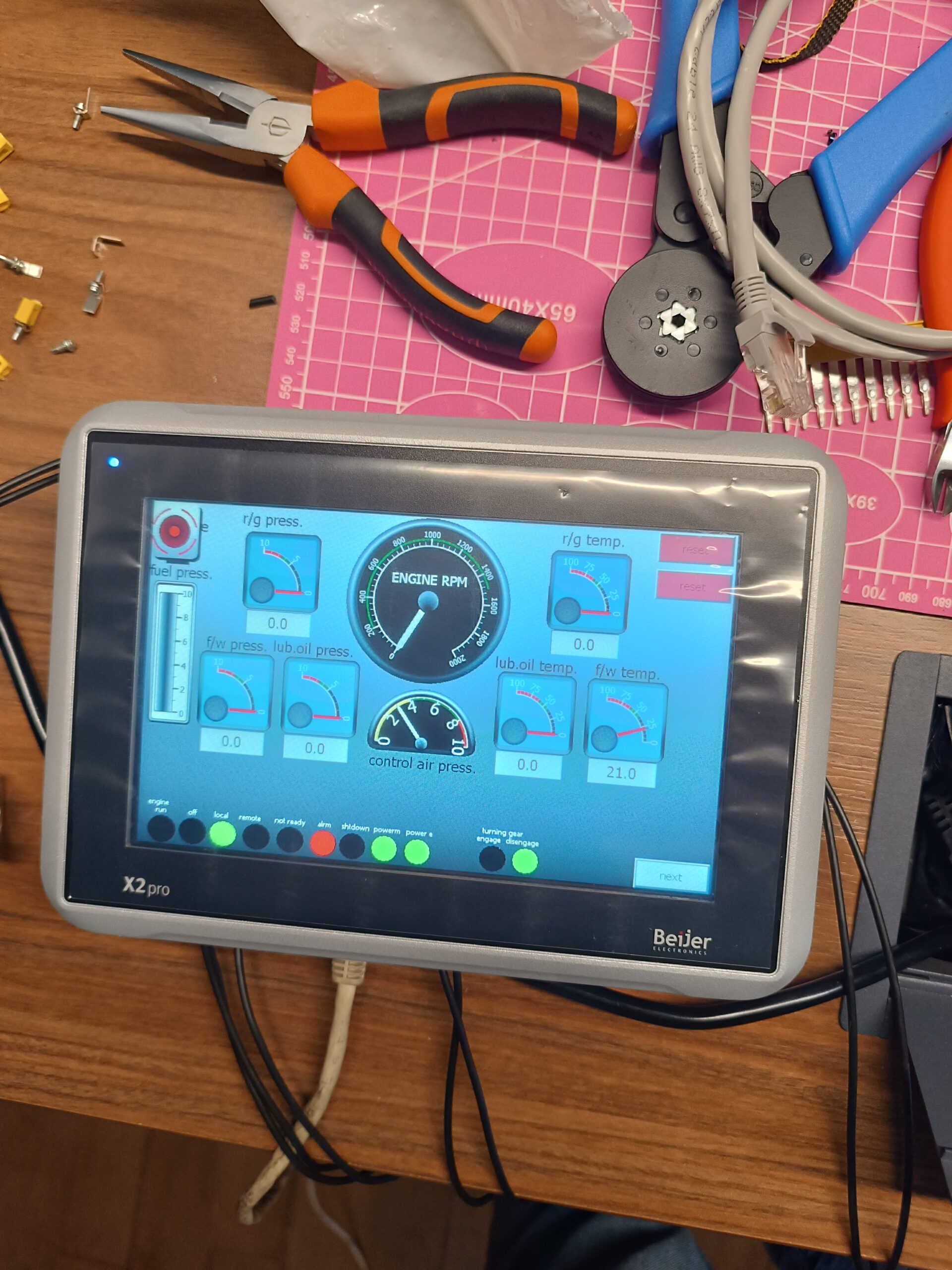

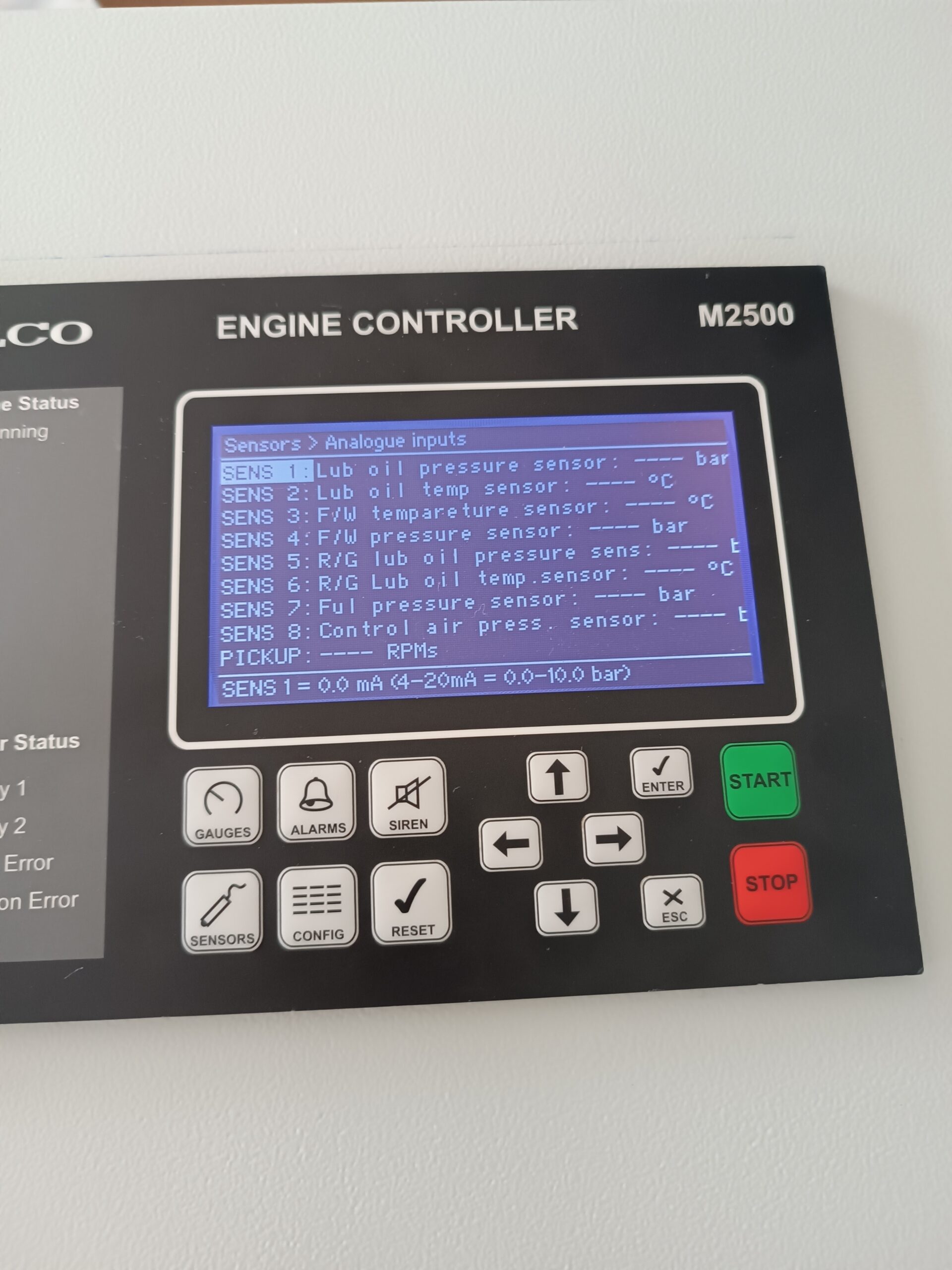

Software Programming: Skilled technicians program and configure PLCs to meet specific application requirements, including logic programming, HMI (Human-Machine Interface) design, and communication protocol setup. They ensure that PLC software is tailored to the unique needs of each system, optimizing performance and functionality.

Diagnostic Services: Comprehensive diagnostic services involve identifying and troubleshooting issues within PLC-based systems. Technicians use advanced diagnostic tools and software to pinpoint the root cause of problems, whether they’re related to software bugs, hardware failures, or communication errors.

Firmware Updates: Regular firmware updates are essential for keeping PLCs up-to-date with the latest features, security patches, and bug fixes. Service providers ensure that PLC firmware is updated safely and efficiently, minimizing the risk of compatibility issues or system downtime.

Hardware Repair and Replacement: In the event of hardware failures or component malfunctions, skilled technicians perform repairs or replacements to restore functionality. This may involve repairing damaged circuit boards, replacing faulty modules, or sourcing compatible replacement parts to ensure seamless integration with existing systems.

System Upgrades and Expansion: As industrial automation requirements evolve, system upgrades and expansion may be necessary to accommodate new processes or technologies. PLC support services include planning, implementation, and testing of system upgrades, ensuring minimal disruption to operations and maximum compatibility with existing infrastructure.

Benefits of PLC Software and Hardware Support:

- Minimized Downtime: Prompt troubleshooting and repairs minimize downtime, ensuring continuous operation of industrial processes and maximizing productivity.

- Optimized Performance: Regular maintenance and updates optimize the performance and efficiency of PLC-based systems, improving throughput and reducing operational costs.

- Enhanced Reliability: Comprehensive support services enhance the reliability and uptime of PLCs, minimizing the risk of unexpected failures and costly repairs.

- Increased Flexibility: System upgrades and expansion enable organizations to adapt to changing business requirements and technological advancements, maintaining competitiveness in the market.

- Expert Guidance: Access to skilled technicians and engineers provides expert guidance and support, empowering organizations to make informed decisions and leverage the full potential of their automation systems.

Conclusion: In conclusion, PLC software and hardware support services are indispensable for maintaining the performance, reliability, and longevity of industrial automation systems. By investing in comprehensive support services, organizations can minimize downtime, optimize performance, and stay ahead of the curve in today’s competitive market. Whether it’s through software programming, diagnostic services, hardware repair, or system upgrades, partnering with experienced PLC support providers is essential for maximizing the efficiency and productivity of industrial processes.

- Competitive rates

- Advanced technology

- 24/7 support

- Always on time

- Fast and realiable

- Safe packaging