All Services

- Tank Valve Remote Control System Services

- Alarm Monitoring & Tank Gauging Monitoring System Services

- Main Switchboard & Loadsharing Maintanence And Repair Service

- Engine & Aux Gen. Governor System Repair

- Alternator System Repair Services

- Automation and Electric Electronic Spare Part Support

- Automation Service

- Electronic Card Repair

- PLC Software and Hardware Support

- Deck Crane Automation Repair Service

Do you need support?

Introduction: Deck cranes are vital equipment onboard ships and offshore vessels, facilitating cargo handling, lifting operations, and other essential tasks. The automation systems that control these cranes play a critical role in ensuring safe and efficient operations at sea. However, like any machinery, deck crane automation systems can encounter issues that require prompt repair and maintenance.

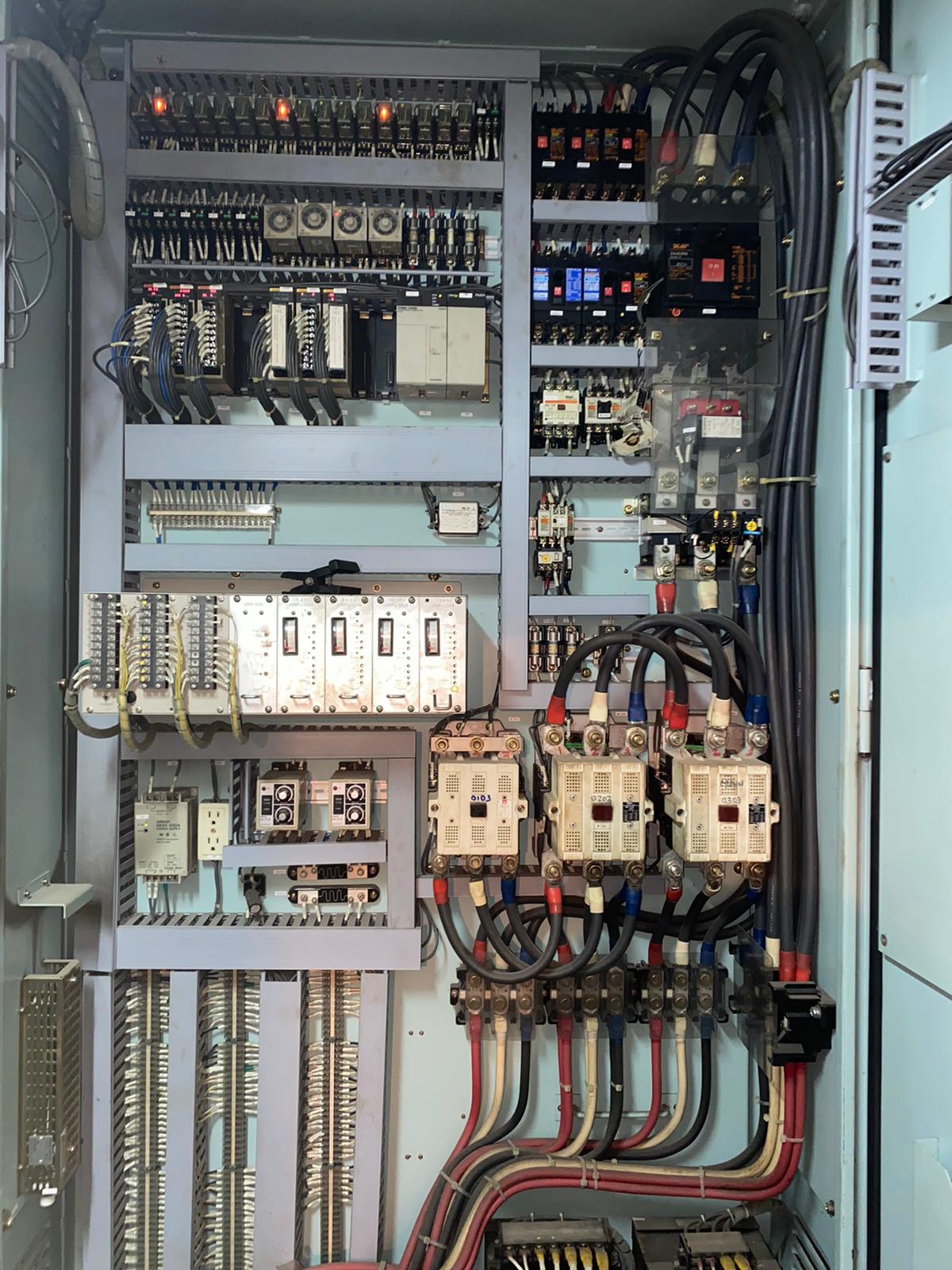

Understanding Deck Crane Automation Systems: Deck crane automation systems are complex arrangements of sensors, actuators, control panels, and software that enable precise control and maneuverability of the crane. These systems are responsible for functions such as load monitoring, position sensing, anti-sway control, and emergency stop mechanisms. Any malfunction or breakdown in the automation system can disrupt cargo operations, compromise safety, and lead to costly downtime.

The Significance of Repair Services: Deck crane automation repair services are essential for addressing a wide range of issues that may arise during the lifecycle of the equipment. Whether it’s a malfunctioning sensor, a faulty control module, or software glitches, skilled technicians are equipped to diagnose, troubleshoot, and repair the automation system to restore full functionality. These services not only ensure the safety and efficiency of cargo handling operations but also minimize downtime and maintenance costs for shipowners and operators.

Key Aspects of Deck Crane Automation Repair Services:

Diagnosis and Troubleshooting: Experienced technicians conduct thorough diagnostics to identify the root cause of automation system issues. This may involve testing sensors, analyzing control signals, and inspecting electrical connections to pinpoint faults accurately.

Component Repair and Replacement: Upon diagnosis, technicians perform necessary repairs or replacements on components such as sensors, actuators, PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), and control panels. They ensure that repaired or replaced components meet the required specifications and standards for maritime use.

Software Updates and Calibration: Regular software updates and calibration are essential for maintaining the performance and reliability of deck crane automation systems. Technicians ensure that software patches are applied, firmware is updated, and system parameters are calibrated to optimize functionality and accuracy.

Preventive Maintenance: In addition to reactive repairs, preventive maintenance is crucial for proactively addressing potential issues before they escalate. Technicians conduct routine inspections, lubrication, and testing to identify early signs of wear or degradation and perform necessary maintenance tasks to prevent breakdowns.

Emergency Response Services: For critical failures or emergencies at sea, deck crane automation repair services offer rapid response capabilities to address urgent issues and restore operations promptly. Technicians are available round-the-clock to provide remote assistance, onsite repairs, or emergency parts delivery to minimize downtime and mitigate risks.

Conclusion: In conclusion, deck crane automation repair services are indispensable for ensuring the safety, efficiency, and reliability of cargo handling operations at sea. By investing in skilled repair and maintenance services, shipowners and operators can minimize downtime, reduce operational risks, and optimize the performance of their deck crane automation systems. Whether it’s through diagnosis, component repair, preventive maintenance, or emergency response, partnering with experienced service providers is essential for maintaining uninterrupted operations and upholding the highest standards of safety in maritime environments.

- Competitive rates

- Advanced technology

- 24/7 support

- Always on time

- Fast and realiable

- Safe packaging